to make handlebars for trials bikes. The name is a combination - REN from Renshaw and the THAL from Rosenthal.

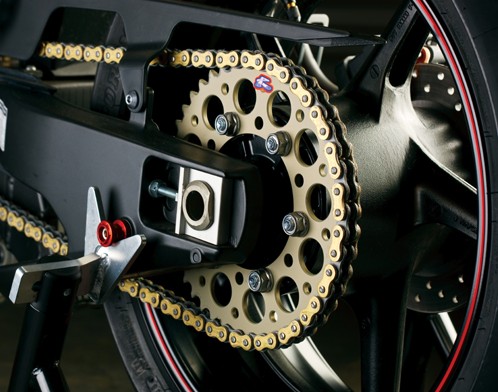

In 1975 Renthal sprockets entered the

motocross market with full time production in

Manchester, Northern England,

the very same place where the company resides today. The

company had steady growth through the 70's and 80's

and finally broke into the US market in the early 90s.

Renthal currently employs over 60 production staff

and Renthal sprockets are sold in 42 countries

worldwide.

In October 2000, Renthal's factory was destroyed by a

massive fire. What replaced the original factory was a

completely new,

state of the art manufacturing and design facility.

Renthal's 41,000 sq. ft. factory now uses the most state

of the art equipment

available for manufacturing, quality control, R&D, and

storage. This includes five Yamazaki two and three axis

CNC turning centers,

seven Kitamura machining centers, one Kardex Shuttle

500NT automated vertical storage system, and a number of

other custom specification machines. These custom spec

machines include bar bending machines, a fatigue tester

and drop test rig

created to fatigue aluminum handlebars.

In 2004, Renthal sprockets added to its list of

records, becoming the first aluminium handlebar to be

fitted as OE

on a Japanese off-road motorcycle, possibly one of the

highest accolades of quality a company in this industry

could receive.