ORDERS:

704-799-2192

![]()

BIKE SPECIFIC

PARTS PAGES

FOR NEW

'03-'22 Models

(Grom, Monkey

Z125, RC390,

R3, R1, R6,

ZX-10, ZX6

CBR's, GSX-R's

& more)

![]()

"VIC" Repeat

Customer Discount

Program

TOP SELLERS

Ohlins Shocks,

Forks, & Dampers

Antigravity

Superlight

Lithium Batteries

PRODUCT CATEGORIES

Air Filters

Engine Parts

Exhaust

Fairing Stay

Head Set

Communications

Helmets

Mirrors / Mirror Block Off Plates

Race Stands

Radar Detectors

Radiator Hose Kits

Tank Traction Pads / Stomp Grip

Throttle Lock / Cruise Control

Tire Pressure Monitoring (TPMS)

Windscreens

Zombie Target

NecksGen

"VIC" Repeat

Customer Discount

Program

DYNO JET MULTI-Function HUB - Guide

<< -

BACK TO

LCD & HUB MAIN PAGE

SPEED INPUT

- (harness #76950212)

SPEED INPUT

- (harness #76950212)

Most modern fuel injected bikes use a transmission speed sensor. The Hub can be

tapped into this sensor to display vehicle speed and

also to be used as a gear position display for bikes that do not have a rotary

type sensor

1 Locate the signal wire of the speed sensor (refer to the service manual, NOTE

section of this guide, or www.powercommander.com).

2 Crimp the supplied wire tap to this wire.

3 Connect the BROWN wire from the HUB harness to the wire tap.

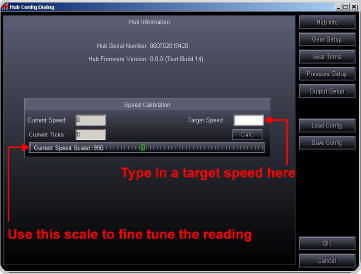

4 If there is not a configuration file for your bike then you will need to

calculate the speed input manually. Go to POWER

COMMANDER TOOLS - HUB CONFIGURATION. Type in a target speed (20-40mph). The bike

will need to be put in

gear and held at the target speed. Once the speed is stable click on CALC. The

current speed should now read the

same as the dash. For the most accurate results this is best done on a

dynamometer although this can be achieved

with the bike on a rear stand.

The Speed Scaler can be used to fine tune the speedometer reading in the PCIII

software or the LCD display. If you

were using a GPS you could move the scale until the LCD display coincided with

the GPS display.

GEAR POSITION -

(harness #76950212)

GEAR POSITION -

(harness #76950212)

Gear Position can be calibrated on bikes that have a rotary switch and/or a

transmission speed sensor.

Gear Position can be calibrated on bikes that have a rotary switch and/or a

transmission speed sensor.

If desired both the speed input and gear input could be used simultaneously

If your bike has a rotary gear position sensor then you

will need to determine which wire from the sensor is the signal (refer to the

service manual, NOTE section of this guide or www.powercommander.com). Most

Kawasakis and Suzukis use a rotary type sensor.

2 Crimp the supplied wire tap to this wire.

3 Connect the GREY wire from the Gear Position Hub harness to the wire tap. If

your bike does NOT have a rotary type

sensor then the GREY wire will not be used.

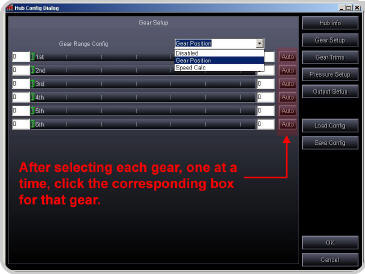

4 To setup the Gear Position Input go to POWER COMMANDER TOOLS - HUB

CONFIGURATION - GEAR SETUP. Click

on the drop menu at the top, center of the screen. Choose Gear Position if you

are connected to a rotary type sensor.

5 Put the bike in first gear and click on the Auto box for first gear. Repeat

this step for each gear. This is best performed

on a dyno but can also be done with the bike on a rear stand. The Green slider

bar should be at different ranges of the

scale for each gear. If the slider bar does not move then you may not have a

good connection at the rotary switch/speed

sensor. Click OK when done.

6 If you are using the speed input for calculating gear position then choose

Speed calc from the drop down menu. Repeat

step

5. Make sure you have calibrated your speed input before performing this

step.

7 After the gear position has been calibrated the main screen of the software

will show current gear position. If the HUB is

connected to the Dynojet LCD display gear position will also be shown.

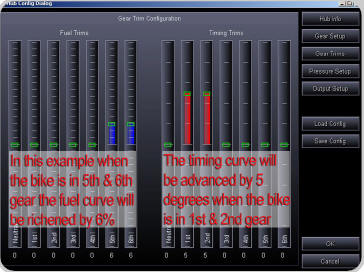

GEAR POSITION TRIM FEATURE -

After you have setup the gear position either via the rotary sensor or

speed input the software will allow

you to trim the base map for both fuel and ignition (if the Ignition Module is

installed).

Go to POWER COMMANDER TOOLS - HUB CONFIGURATION - GEAR TRIMS.

The software will allow you to trim your base map +/- 30% of fuel and +/- 10

degrees of timing per gear.

The software will only allow you a total of +10 degrees of timing so

if your base map has a value of 10 in any cell the gear trim will not allow you

to advance any further. If you had a +5 anywhere in your base timing map and you

tried to move one of the gear trims for

the timing to more than +5 the software would limit you also. Click on the

slider bar and drag to the desired setting for each gear. The offset value will

be shown underneath each scale. Click OK when done.

The Gear Position Trim values will be added to the base map values and will be

displayed under fuel change

and/or timing on the main software screen.

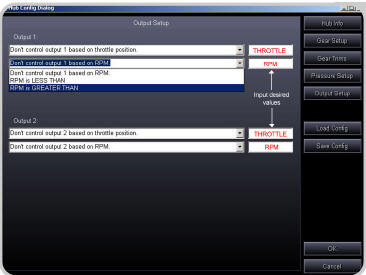

RELAY TRIGGER -

(harness #76950506)

The Hub can trigger up

to 2 output signals such as an indicator light, Nitrous relay, or shift light.

The Hub can trigger up

to 2 output signals such as an indicator light, Nitrous relay, or shift light.

1 Locate the ground wire of the device you want to

trigger.

2 Attach the ground from the device to the HUB harness.

3 Attach the WHITE/YELLOW wire from the Hub harness to trigger Output Channel 1.

4 Attach the WHITE/GREEN wire from the Hub harness to trigger Output Channel 2

(if needed).

5 Attach the BLACK wire from the Hub harness to a chassis ground or the negative

side of the battery.

6 Go to POWER COMMANDER TOOLS - HUB CONFIGURATION - OUTPUT SETUP. The trigger

can be

activated based on Throttle Position and/or RPM. For example; you could trigger

a NOS relay to only be

activated above 80% throttle and above 7000rpm. Click OK when setup is done.

PRESSURE INPUT (harness #76950012)

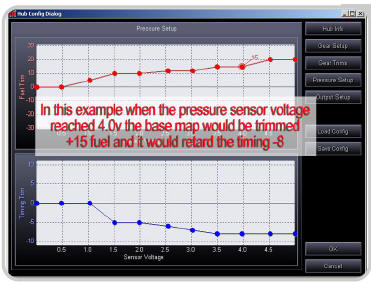

The Pressure input harness allows you to trim the base fuel/timing map based on

a 0-5v input line. In most

cases this will be used to offset the fuel curve for a turbo application.

You will first need to determine the parameters of the pressure sensor that you are using. If the sensor reads a maximum of 10lbs of pressure then you will need to determine what the voltages correspond to at 1lb and at 10lbs. Every point in between should be a linear reading. Refer to the notes section for readings of specific sensors. Once you have determined the parameters of your sensor you can alter the HUB settings accordingly. For example, if you wanted the HUB to add 10% of fuel at 5lbs of boost then move the scale to +10% fuel to the voltage that you determined your sensor would be at when it read 5lbs of boost. You can also trim the ignition timing according to a pressure input if desired. The HUB will allow you +/- 50% of fuel and +/-10 degrees of timing on top of your base map. The software will only allow you a total of +10 degrees so if your base map has a value of 10 in any cell the pressure trim will not allow you to advance any further. The raw voltage of this sensor will be displayed on the main software screen under Trim Voltage.

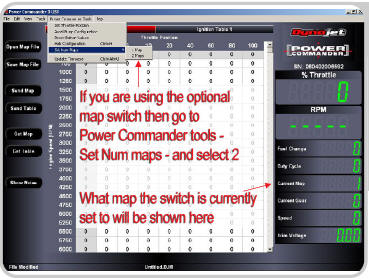

MAP SWITCH

(harness #76950320)

MAP SWITCH

(harness #76950320)

Map switch is shown mounted to the handlebar via our optional map switch bracket

part #61329304 Note: Bracket is for 7/8 bars.

The map switch will allow you to toggle back and forth between two maps that are

saved within the Power Commander. To enable this feature go to POWER COMMANDER

TOOLS - SET NUM MAPS - 2 MAPS. When this feature is enabled when you click on

Send Map or Get Map you will be prompted as to what map you want to send or

receive. The map that is currently active in the Power Commander will be

displayed on the right hand side of the software. When first connecting to the

software it will automatically retrieve the map that the switch correlates to.

When tuning the PCIII USB and using either INSERT (on keyboard) or SEND TABLE

and you are viewing the map that is NOT current you will be prompted that you

are about to alter the incorrect map. Follow the

instructions shown on the screen to continue.

LOAD/SAVE CONFIG

Under Power Commander Tools - Hub

Configuration, you will see you have the option of either LOAD or

SAVE config files. We have compiled the setup information needed for various

models which saves you

setup time when using the SPEED and/or GEAR input harnesses. These configuration

files can be found at

www.powercommander.com. Download these files to your computer and when you click

on LOAD config

from the HUB setup it will prompt you to find this file. Once the file is loaded

the necessary settings should

be filled in under SPEED and GEAR input. These settings can be loaded even if

you are not using these

harnesses though no data will be displayed. We will be constantly adding new

models to the list so keep an eye on the website for new updates.

GEAR/SPEED INPUT

Most of the Suzuki and Kawasaki models have a

rotary style gear position indicator. This sensor can be located on the

shift drum inside the transmission which outputs different voltages in each

gear. When connecting the Gear input har

ness from the HUB to this style of sensor it will give you a very stable gear

reading. This sensor will normally have 3

wires. One wire is Ground, one wire is constant 5 volts, and the wire you need

to connect to will have variable voltage

when the bike is running and you shift thru the gears.

If you are using a timing retard device that connects to the gear position you

will need to base the HUB gear position on

the speed input.

The speed output sensor will normally have 3 wires. One wire is Ground, one wire

is constant 5 volts and the one you

need to connect to will have variable 0-5volts when the bike is running and the

rear wheel is spinning.

Here is a list of the location of these wires on some models. Check the website

for a more updated list.

<< -

BACK TO

LCD & HUB MAIN PAGE