ORDERS:

704-799-2192

![]()

BIKE SPECIFIC

PARTS PAGES

FOR NEW

'03-'22 Models

(Grom, Monkey

Z125, RC390,

R3, R1, R6,

ZX-10, ZX6

CBR's, GSX-R's

& more)

![]()

"VIC" Repeat

Customer Discount

Program

TOP SELLERS

Ohlins Shocks,

Forks, & Dampers

Antigravity

Superlight

Lithium Batteries

PRODUCT CATEGORIES

Air Filters

Engine Parts

Exhaust

Fairing Stay

Head Set

Communications

Helmets

Mirrors / Mirror Block Off Plates

Race Stands

Radar Detectors

Radiator Hose Kits

Tank Traction Pads / Stomp Grip

Throttle Lock / Cruise Control

Tire Pressure Monitoring (TPMS)

Windscreens

Zombie Target

NecksGen

"VIC" Repeat

Customer Discount

Program

|

CAN YOU

REALLY TELL |

How to recognize the essential elements of a good exhaust system |

|

In our years of experience on the aftermarket

exhaust components market and encounters with the competition, we have

gained a great deal of knowledge. There is a surprising number of

exhaust system manufacturers whose products vary widely in terms of

development and quality. Even with a quick glance we can distinguish a

high-quality and successful manufacturer from one who is following the

trend-setters in any way they can. We find it troubling that some of

these manufacturers pay little attention to the quality of their

products, and therefore to their customers and their safety. |

|

|||

|

|

|||

| COMPETITION |

|

AKRAPOVIC |

|

|

HEADER TUBES |

|||

|

|

||

|

Akrapovic header tubes together with conical elements made using the hydroforming process, with which we ensure the optimal flow of the exhaust gases, i.e. minimize the negative turbulence of the gases. |

|||

|

|

||

|

No springs to attach header tubes to the head of the engine: - header tube inner sleeves are welded to the header tubes and do not allow the flanges to be removed from the header tubes. This means that the inner sleeve, header tube and flange cannot be separated. Since the header tubes are attached via the flanges directly to the head, the header tubes cannot be removed quickly. - this type of attachment causes engine vibrations to be transferred directly to the material and welds of the exhaust system (increased material stress). |

Inner sleeves, flanges and header tubes are independent. Therefore the header tubes are “free-floating”, and are attached to the engine head using springs. They are not bolted in. Only the flanges are screwed in, and these hold the inner sleeves. This system allows faster removal and installation of the header tubes in racing situations. Stress on the material due to engine vibration is reduced to a minimum. |

||

|

|

||

|

Interference crossover tubes are made without reinforcement, which due to the use of titanium could result in cracking of the joints. |

Due to our experience, we always reinforce our titanium interference crossover tubes. |

||

|

|

||

|

All joints on the individual components are made by expanding the material and not with CNC machined sleeves. The expanded joints gradually become stressed and crack – the material becomes worn. This approach significantly reduces the compactness of the configuration, i.e. allows unwanted play in the joints, thus allowing the individual system components to move. |

The joints between individual components are made from CNC machined sleeves. Only in this way, using allowable tolerances, can we ensure constant precise contact between individual components and permanent compactness of the system. |

||

|

EYE LETS |

|||

|

|

||

|

Eyelets for attaching the springs are made out of too-thin material. The spring gradually cuts through the material and wears out the eyelet at the contact point. |

We use a special type of titanium which is not subject to the mechanical influences of the steel springs. | ||

|

MUFFLER |

|||

|

|

||

|

The opening on the inlet cap of the muffler (muffler – link pipe joint) is again made using expansion (see HEADER TUBES) |

The opening

on the inlet cap of the muffler (muffler – link pipe joint) is, like all

our joints between individual components (header tubes – collector –

link pipe) made from a CNC machined sleeve. |

||

|

|

||

|

The interior packing of the muffler is damping wool (E-glass). It lacks additional protection against strong engine pulses, which leads to faster wearing out of the muffler packing. |

In addition to the damping wool, the interior of the muffler contains an SS mesh/SS wool/SS mesh sandwich, which prevents excessive combustion of the muffler packing material under heavier loading. |

||

|

MUFFLER CLAMP & BRACKET |

|||

|

|

||

|

Muffler clamp made of cheap stamped stainless steel with a rubber washer. The rubber in this case acts as an insulator, which can lead to an unwanted effect – local overheating of the muffler (at the point where the washer touches muffler the outer sleeve). Muffler bracket made of aluminum. |

To attach the Akrapovic muffler to the motorcycle frame we use an in-house developed carbon-fiber clamp and carbon-fiber bracket. With the use of this material we avoid local overheating of the muffler outer sleeve, and due to the flexibility of the clamp and bracket the vibrations of the frame and the exhaust system are sufficiently damped. The low weight of carbon fiber lowers the overall weight of the system. |

||

|

WELDING AND STRUCTURE OF INDIVIDUAL PARTS OF TUBES |

|||

|

|

||

|

Irregularities in the welds in certain parts of the component: insufficient reheating and fusing of the materials – a weld which looks good on the outside does not guarantee hardness, soundness and therefore safety. |

The perfect fit of individual tube parts around their circumference is extremely important, since this makes accurate welding possible only where it is needed. We avoid weld leakage into the interior of the tube, which acts like an unwanted scar on the interior tube surface, disrupting the smooth flow of exhaust gases and distorting the system’s performance characteristics. |

||

|

MATERIAL |

|||

|

|||

|

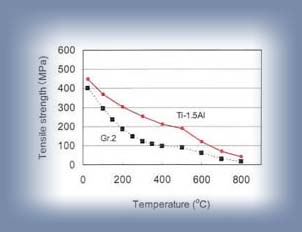

The system we obtained uses grade 1 or grade 2 titanium, i.e. so-called commercial pure titanium, which does not satisfy all of the stress conditions which appear during the operation of the exhaust system. Grade 1 or grade 2 titanium is not sufficiently temperature resistant, as it tolerates temperatures only up to 300º - 400ºC. The temperature of exhaust gases when exiting the engine head can reach up to 800ºC. |

Akrapovic uses a special type of titanium for its Evolution exhaust systems. On the basis of an exclusive contract with Japanese manufacturer Kobe Steel, we have a concession for a special titanium alloy intended exclusively for the production of Akrapovic exhaust systems. This alloy conforms to grade 3 level of tensile strength and resistance to oxidation at high temperatures. According to specifications, at 800ºC this alloy must tolerate one level of tensile strength higher than grade 2 titanium. At temperatures between 200 and 500 ºC it must demonstrate up to 3x higher strength (red line). This alloy also responds very well to forming and is easy to weld. |

||